| In

1997, we became aware of a serious silting problem under the Ameristar

Casino's 630-ft. long, by 230-ft. wide, barge flotilla located on the

Missouri River at St. Charles, Missouri. Silt and large mounds of

driftwood had built up under the barges, and the flotilla were in danger

of setting on ground. This would have caused the casino to be closed.

Ameristar searched world wide for a dredging method that would remove

the silt and driftwood without having to move the barges. Two widely

acclaimed methods were tried. Both methods failed. One of the failed

methods was patented. The patented method caused one of the barges to

buckle, and replacement cost the Casino over $400,000.

Dredging Specialists was contacted and agreed to develop a dredging

system to solve these problems. Research and engineering lead to the

development of a drag scraper dredging system that would perform the

required dredging. The casino then commissioned us to build and operate

this system. To do the dredging work, a joint venture was formed with

Limited Leasing of Bridgeton, MO.

The Material: From the upriver end of the flotilla, there was soft

sticky mud that extended about 150-ft. downriver. If you tried to walk

on this mud, you would sink up to your knees. The material then changed

to layers of mud and sand. Further downriver, the material became hard

packed sand that you could drive a truck on. There were several spuds

and dolphins that held the flotilla in place. Around the spuds and

dolphins, there were huge piles of driftwood and root balls. Some of the

logs were up to 2-ft. in diameter. The driftwood was entangled like a

bird nest and buried in the mud. To provide sufficient water to keep the

flotilla floating during times of low water, required the removal of

material up to 22-ft. deep. It is necessary to dredge a depth of 12-ft.

to 18-ft of material each summer.

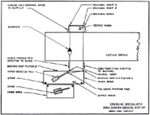

The System

View Drag

Scraper System

|

|

The Drag Scrapers: During the first year, we used Sauerman scrapers.

Because of the vastly different types of material and the driftwood, we

had many problems with these scrapers. We then designed and built our

own scrapers. We made model scrapers to 1/8-scale and used them to

conduct extensive tests in a test facility that we built.

Our tests

revealed several keys to effective scraper design and operation. Our

scrapers will dig down and fill with material. When the scraper gets

full, it will stop digging down, will raise and drag the material. When

the scraper is out from under the flotilla, the scraper is stopped and

then pulled back. The material in the scraper is deposited when the

scraper is pulled back. Our scrapers will dig soft mud as well as hard

sand. Our scrapers have successfully removed the piles of entangled

driftwood.

We use a four cubic yard drag scraper with an open bottom and an open

top. This scraper is 4-ft. high. We also have a scraper that is 18-in.

high. The small scraper is used when the barges are on ground. With our

small scraper, we were able to dredge the barges off the ground. |

| |

View Drag

Scraper Bucket

|

The Winch Barge: This barge has a diesel

engine powered 19,000-lb. line pull, triple drum winch. The winch is used to inhaul and back-haul the scraper.

This barge has an

inhaul and back-haul mast, [Explained later], and the required sheaves.

This barge also has a service winch, large

operators cabin, tool and supply trailer, welders and other support equipment.

The Crane Barge: This barge is placed

beside and out-river from the winch barge. An

80-ton crawler crane is used to raise and lower the spuds on both the winch and crane

barges, to launch and recover the scraper, to handle supplies and for general service

work. By using the crane and winch barge

together, we are able to step the barges downriver on ropes and upriver with the service

winch.

The Back-Haul Barge: This barge provides

masts and the sheaves needed to pull the scraper back.

During dredging, it is rigidly rigged with cables to D rings that are welded

to the shore side of the flotilla. It has a

hydraulic system and cylinders to tension the cables.

service winch is used to reposition the barge along the side of the

flotilla.

The Masts: The winch cables cannot rub on the

bottom of the casino barges. Some of the

casino barges have a draft of 7-ft. This

required that we provide heavy structures that placed the sheaves and winch cables 8-ft.

under the water. We call these structures

mast piles. I will use the term mast.

The inhaul cable runs

from the winch to the inhaul mast upper sheave. It

then turns 90 degrees and goes straight down to the inhaul mast lower sheave, that is

8-ft. under water. The cable then turns 90

degrees and runs horizontally to a chain bridal at the front of the scraper.

The back-haul cable runs

from the rear of the scraper to an underwater sheave on the lower end of the #1 mast on

the back-haul barge. The cable then runs up

the mast, turns 90 degrees and runs to the top sheave on the #2 mast, that is located on

the other end of the backhaul barge. The

cable runs down the mast to an underwater sheave, where it turns 90 degrees and runs back

to the winch barge. At the winch barge, the

cable runs from an underwater sheave on the back-haul mast, up the mast to an upper

sheave, then to a two sheave Christmas tree, and then to the winch. The back-haul mast on the winch barge can be moved

to position # 2. This permits working from

upriver to downriver, regardless of which side of a river we are on.

For rigging and service

work, the masts on the winch barge are raised and lowered with the crane. The masts on the backhaul barge are raised and

lowered with hydraulic cylinders. The

bearings on the underwater sheaves are sealed with face type seals. All underwater sheaves will pivot.

The Operation

The Winch Barge and the

Crane Barge are spudded about 100-ft. out-river from the flotilla. The inhaul and backhaul cables are rigged through

the proper sheaves and attached to the scraper. The

crane places the scraper in the water. The

winch pulls the scraper back and forth and the material is dumped out-river from the

flotilla. Dredging is started at the

out-river side of the flotilla and the scraper goes back 5-ft. farther, before being

pulled out on each successive pull.

The wheel of an encoder

runs on the flange of the inhaul top sheave. The

encoder is coupled to a programmable logic controller.

This tells the operator the location of the scraper. The depth of water and cut is determined by

soundings that are made on each side and between the barges of the flotilla. When a 6-ft. depth of material has been removed,

the barges are moved 10-ft. downriver and the process is repeated. When more than 6-ft. of material must be removed,

a second pass is made. Proper placement of

the inhaul cable on the anchor chain bridle, at the front of the scraper, causes the

scraper to remove material from the side of the cut, and this moves the scraper and the

cut downriver. It may be necessary to remove

the material that has been dumped out-river of the flotilla. This can be done by loading the material in barges

with a clam bucket, or it can be removed with a hydraulic dredge.

During the five years

that we have dredged under this casino, we have made over 25 improvements to the methods

and equipment. These improvements have

substantially decreased the casino’s costs. This is part of our commitment to

provide,

Excellence with Knowledge, Experience

and Innovation.

For five years, our Drag

Scraper Dredging System has kept this casino from closing and has saved 1,500 jobs. We do not know of any other dredging system that

could have done this.

Our Drag Scraper

Dredging System will successfully dredge under floating casinos, wharves, dry-docks, barge

flotillas, and large marine vessels and structures that cannot be moved. |